WB8-3

Fabrication of FeSe Superconductors with High Energy Ball Milling Aided Sintering Process

Dec.3 13:30-13:45 (Tokyo Time)

Northwest Institute for Nonferrous Metal Research1

FeSe superconductors exhibit the critical temperature of ~8 K, and 15 K after Te and S substitution at Se site[1, 2]. They have the simplest lattice structure among all the Fe-based superconductors, with only Fe-Se superconducting layers and no blocking layer. It has been reported that the current capacity of both FeSe based single crystals and coated conductor films can reach 106 Acm-2 at 4.2 K, self field[3], and over 105 Acm-2 under 30 T[4]. The high current capacity under high field makes FeSe based superconductors promising candidates for the application in high field magnets.

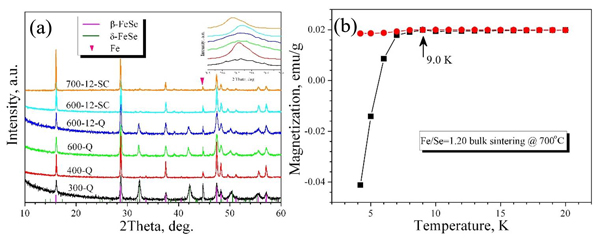

However, it is not quite simple to fabrication single phase FeSe based superconductors, based on the following reasons: 1. The appearance of hexagonal d-FeSe can not be avoided easily. Based on the binary phase diagram, in the Fe:Se~1 region, both the formation of tetragonal b-FeSe and hexagonal d-FeSe will be formed simultaneously. 2. Due to the melting of Se under low temperature, there will leave large content of pores in sintered bulks. Therefore, aiming at the achieving of FeSe based superconducting bulks with high superconducting phase content, a novel sintering technique called high energy ball milling aided sintering process has been developed. By carefully optimizing the key parameters involved in this process, including milling time, ball to powder ratio, sintering temperature, and Fe content, FeSe bulks with high critical temperature of 9.0 K, and superconducting phase ratio of over 95% have been obtained. The phase evolution mechanism involved during the sintering process has also been deduced. The research of this study can provide an effective method for the fabrication of FeSe based superconducting bulks, tapes as well as target for PLD deposition, thus greatly improve the development of Fe based superconductors for practical applications.

[1] Z.N. Guo, H.H. Zhang, B.L. Han, W.X. Yuan, Physica C 509, 29-33 (2016).

[2] F.C. Hsu, J.Y. Luo, K.W. Yeh, T.K. Chen, T.W. Huang, P.M. Wu, Y.C. Lee, Y.L. Huang, Y.Y. Chu, D.C. Yan, M.K. WU, Proc. Natl. Acad Sci USA 105(38), 14262-14264 (2008).

[3] K. Onar, B. Ozcelik, N.K. Fuler, H. Okazaki, H. Takeya, Y. Takano, M.E. Yakinci, J. Alloy. Compd. 683(1), 164-170 (2016).

[4] W.D. Si, S.J. Han, X.Y. Shi, S.N. Ehrlich, J. Jaroszynski, A. Goyal, Q. Li, Nature Commun. 4, 1347 (2013).

Keywords: Fe-based superconductor, high energy ball milling, critical temperature, phase evolution mechanism