AP9-3

Fundamental study of the removal of microplastic fibers using swirling flow and magnetic field

Dec. 1 11:50-12:10

*Satoshi Fujii1, Yoko Akiyama1, Yuichiro Manabe1, Fuminobu Sato1

Graduate School of Engineering, Osaka University (Japan)1

1. Introduction

The impact of microplastics leaking into the environment on the ecosystems is one of the serious issues. One type is microplastic fibers (MPFs), which are contained in laundry wastewater. There is concern that MPFs may pass through sewage treatment facilities and affect the ecosystem by adsorbing toxic substances and their uptake by living organisms.

We have been investigating a method of magnetite adhesion to the surface of MPFs and removal by magnetic force by applying a magnetic field. However, in normal high-gradient magnetic separation systems (HGMS), the magnetic force acting on magnetite exceeds the adhesion force between MPFs and magnetite, causing the magnetite to desorb from the MPFs. To solve the problem, we evaluated the possibility of magnetic separation of MPFs by a magnetic separation system using a swirling flow and magnetic field.

2. Analysis Method

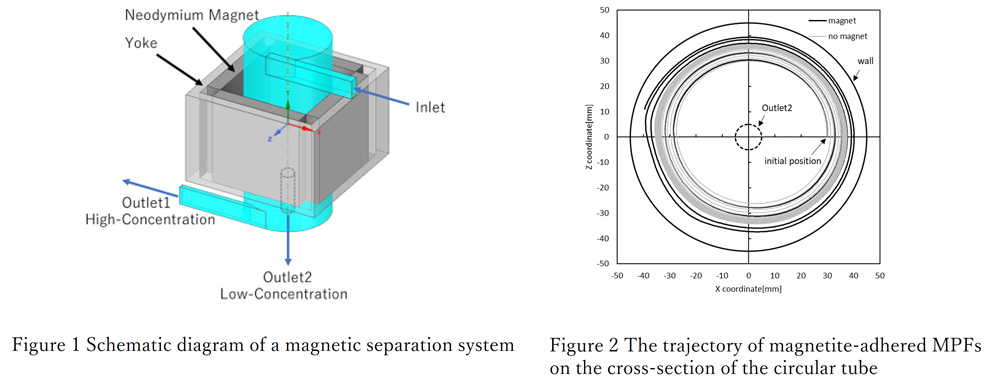

As shown in Figure 1, a flow channel model was created to generate a swirling flow inside a circular tube. This model consists of a circular tube with a radius of 45 mm and a height of 200 mm, with an inlet on the upper side of the tube and outlets on the lower side (Outlet 1) and the center of the tube (Outlet 2).Although the use of opposed superconducting magnets is considered for practical use, for basic study, quadrupole opposed magnets with a maximum flux density of 0.4 T were installed so that the direction of the magnetic force acting on the MPFs is in the radial direction of the circular tube. The velocity and magnetic field distributions in the circular channel were analyzed using finite element method analysis software (Ansys 2021R1, Cybernet Systems Co., Ltd.). Based on microscopic observations of beaker-scale magnetic separation experiments using polyester as MPFs, we assumed that 1,700 magnetite particles (0.5 µm in diameter) adhere to one MPFs of 400 µm in length and 10 µm in diameter. The motion equations for the particles considering magnetic and drag forces are solved in time evolution using the fourth-order Runge-Kutta method to analyze the position of the particles on the cross-section of the circular tube at the center of the magnetic field region.

3. Results and Discussion

The trajectory of magnetite-adhered MPFs on the cross-section of the circular tube at the center of the magnetic field region is shown in Figure 2. Comparing the trajectory of the MPFs with and without the magnet, it was found that the MPFs were directed toward the wall due to magnetic forces. This is because the magnetic flux density in the channel is almost 0 T around the center whereas 0.4 T at the wall, resulting in magnetic forces acting on the MPFs in the wall direction. MPFs flowing into the channel gather in the direction of the wall due to the swirling flow but are further efficiently pulled in the direction of the wall by the assisting magnetic force. Thus, it is expected to cause a high concentration of MPFs simulated wastewater to flow out of Outlet 1 at the side and a low concentration to flow out of Outlet 2 at the center. In addition, the use of superconducting magnets allows the application of a magnetic field over a wide area, making it possible to increase the radius of the circular tube, which would enable the high-speed mass processing of wastewater.

4. Conclusion

Simulated wastewater containing magnetite-adhered MPFs flowed into a channel that generates a swirling flow, and the trajectory of the MPFs was analyzed when a magnetic field was applied by a quadrupole opposed magnet and without a magnetic field. The results show that it is possible to achieve high concentrations of MPFs by applying a magnetic field near the wall surface, compared to the case of only swirling flow. Based on these results, it is expected that high-efficient MPFs removal can be achieved by a magnetic separation system assisted by a swirling flow and magnetic field. For practical use, we plan to conduct further simulations and experiments to clarify the conditions necessary for the efficient removal of MPFs.

Keywords: microplastic fibers, swirling flow, magnetic force, magnetite