WB8-6

Trapping Magnetic Field in a Bulk Iron-based Superconductor Sintered under High Pressure

Dec. 1 15:15-15:30

*Wenxi Wu1, Sunseng Pyon1, Tsuyoshi Tamegai1

Department of Applied Physics, The University of Tokyo1

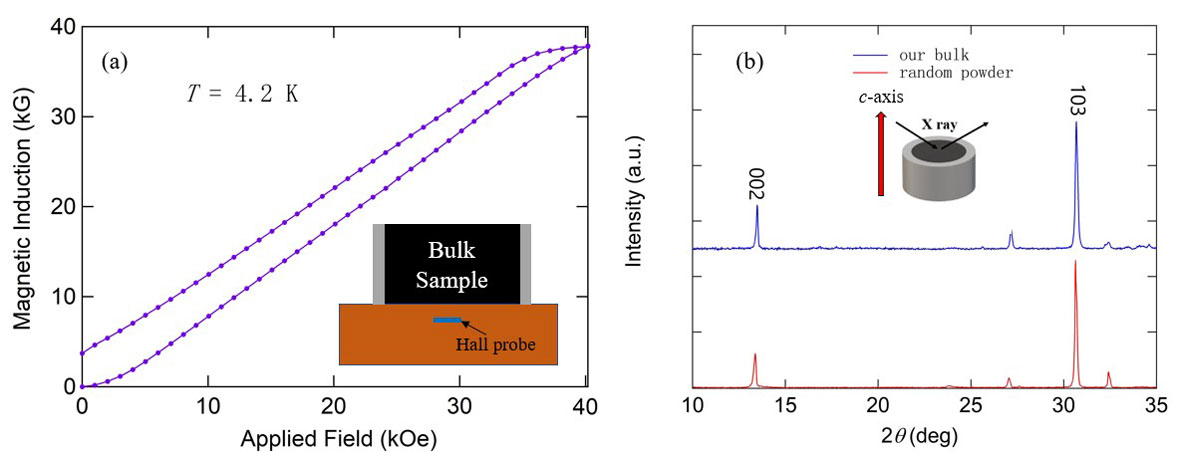

Superconductors with a large critical current density (Jc) can trap a high magnetic field when their powders are pressed into bulk and sintered, which could be used as superconducting magnets. In this work, we attempted to improve the Jc characteristics and trapped field of bulk iron-based superconductors by increasing the pressure used in the manufacturing process. In this work, we attempted to improve the Jc and the trapped field of bulk iron-based superconductors by increasing the pressure used in the manufacturing process. In the present study, we prepared a cylindrical bulk polycrystalline Ba0.6Na0.4Fe2As2 superconductor with a diameter of 3.9 mm and 2.06 mm in thickness. Polycrystalline powder was synthesized by the mechanochemical method as described in Ref. [1] and was sealed in a silver tube with an inner diameter of 4 mm. A cold press process was performed in the glove box to texture the grains along c-axis. The sample was then put into a cubic press and sintered under a pressure of ~2.2 GPa at ~850 for 1 hour. The critical temperature of this bulk is ~33 K. A Hall probe was set at the position z ~0.38 mm from the bottom surface of the bulk to measure the trapped field as shown in the inset of Fig. 1(a). Measured magnetic induction at 4.2 K as a function of the applied field is shown in Fig.1 (a). In the remanent state, measured magnetic induction is ~3,718 G. Jc under the self-field is estimated by Biot-Savart approximation [2] to be ~65.9 kA/cm2, which is larger than that in the previous work [3] but lower than the value in high-quality wires [1]. The trapped field on the surface of the bulk was finally calculated by the same approximation to be ~7,200 G. From XRD result measured on the top surface of the bulk (Fig. 1(b)), it can be seen that the ratio between the intensity of (002) peak and that of (103) peak increased from ~1/5 in random powder to ~1/3 in the bulk, suggesting that grains are textured along c-axis. However, this ratio is still much lower compared with the result in well-textured tapes [4]. We will next try to use higher pressure for the cold pressing to enhance the texturing and to further improve Jc and trapped field.

[1] S. Pyon et al.,Supercond. Sci. Technol. 33, 065001 (2020).

[2] T. Naito et al., Supercond. Sci. Technol. 25, 095012 (2012).

[3] J. D. Weiss et al., Supercond. Sci. Technol. 28, 112001 (2015).

[4] Z. Gao et al.,Sci. Rep. 4, 4065 (2014).

Figure 1 (a) Magnetic induction close to the surface of the Ba0.6Na0.4Fe2As2Ba0.6Na0.4Fe2As2 bulk sample measured by a Hall probe as a function of applied field at 4.2 K. (b) X-ray diffraction patterns of the bulk sample and reference randomly-oriented powder.

Keywords: iron-based superconductor, bulk magnet, high-pressure sintering